Equipment & Configurations

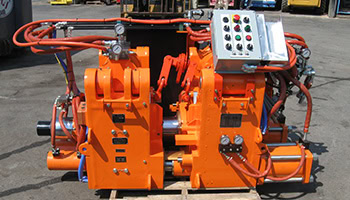

Holland welders are known for their flexibility and longevity. Our low sensor systems are durable with replaceable electrode inserts that lower the cost of operation. Proven from heavy haul to high-speed rail, our welders ensure precision whether welding new rail or old to new. Coupled with the Intelliweld Control System, the welders’ automated alignment features and shearing systems ensure precision and quality.

Our Container Welders provide the complete welding package, including a battery, genset or shore power options and multiple crane configurations. They can be used as a stationary welding machine to generate long welded rail sections or on a customer-supplied mobile carrier to deliver in-track welds.

Our Container Welders provide the complete welding package, including a battery, genset or shore power options and multiple crane configurations. They can be used as a stationary welding machine to generate long welded rail sections or on a customer-supplied mobile carrier to deliver in-track welds. The MobileWelder was first introduced to the industry by Holland in 1979. This versatile flash-butt welding machine is a virtual mobile welding plant that can travel both on rails and on the highway, easily relocating from one job site to another.

The MobileWelder was first introduced to the industry by Holland in 1979. This versatile flash-butt welding machine is a virtual mobile welding plant that can travel both on rails and on the highway, easily relocating from one job site to another.